Understanding Fixed Electrical Testing: Ensuring Safety in Your Electrical Installations

What is Fixed Electrical Testing?

Definition and Importance

Fixed Electrical Testing, known in many sectors as fixed wire testing, is a crucial procedure designed to ensure the safety and compliance of electrical systems within buildings. This process is not merely a routine check, but an essential evaluation aimed at identifying risks associated with the fixed electrical installations, such as wiring, sockets, and circuit breakers. The importance of Fixed Electrical Testing cannot be overstated; it is pivotal in preventing electrical failures that can lead to serious injuries or costly damages.

Components of the Testing Process

The testing process encompasses several essential components. To begin, visual inspections of equipment, wiring, and installation practices are conducted to detect any apparent defects or wear. Following this, detailed electrical tests are performed using specialized instruments to measure resistance, insulation integrity, and continuity of electrical circuits. These tests typically include:

- Earth Fault Loop Impedance Testing: Measures the impedance of the earth fault path to ensure safety

- Insulation Resistance Testing: Assesses the quality of insulation in the electrical wiring

- RCD Testing: Evaluates the effectiveness of Residual Current Devices to prevent electric shock

Key Benefits for Businesses

For businesses, the advantages of regular fixed electrical testing are manifold. First and foremost, it enhances safety by identifying potential hazards, thereby reducing the risk of electrical fires and accidents. Moreover, compliance with regulatory standards mitigates legal liabilities and avoids hefty fines. Ultimately, a robust electrical system optimizes performance and resilience, minimizing downtime caused by electrical failures. As a result, investing in fixed electrical testing not only safeguards employees but also secures the overall operational efficiency of the business.

Legal Requirements and Compliance

Current Regulations in the Industry

Fixed electrical systems must comply with several legal requirements, including national and local regulations. In many regions, the Institution of Engineering and Technology (IET) regulations, specifically the IET Wiring Regulations (BS 7671), serve as the baseline for electrical installations. These regulations stipulate the standards for installation, maintenance, and testing related to safety.

Consequences of Non-Compliance

Failure to adhere to fixed electrical testing protocols can result in dire consequences. Non-compliance can lead to severe safety hazards, exposing workers to life-threatening conditions. Additionally, businesses may face legal repercussions, including lawsuits, fines, and insurance claims arising from accidents linked to inadequate electrical systems. The reputational damage to a company can be tremendous, potentially resulting in lost customers and decreased revenue.

Importance of Certification

Certification after fixed electrical testing is a key aspect of regulatory compliance. A Certificate of Compliance indicates that a building’s electrical installations have passed a thorough inspection and testing process, thus confirming their safety for use. This certificate is not merely a piece of paper; it is an assurance to stakeholders, regulatory bodies, and clients regarding the safety and reliability of the electrical infrastructure.

Common Testing Procedures

Visual Inspections

The first step in the fixed electrical testing procedure is performing a comprehensive visual inspection. Electricians check the general condition of electrical installations, looking for any visible wear, damage, or faulty components like cracked sockets or exposed wires. Moreover, inspectors verify that the installations comply with safety standards and that appropriate labels and signage are present where necessary.

Detailed Electrical Testing Methods

Following visual inspections, qualified electricians utilize a variety of intricate testing methods to assess the operational efficiency and safety of electrical installations. Aside from the previously mentioned testing types, it’s commonplace to perform:

- Polarity Testing: Ensures the correct connection of live, neutral, and earth conductors.

- Functional Testing: Tests the operation of electrical devices under load conditions.

- Thermal Imaging: Detects hotspots in the circuit that may indicate underlying faults.

Interpreting the Test Results

Correctly interpreting test results is essential for ensuring the safety of electrical installations. Qualified electricians will analyze the data collected during testing to classify findings into different categories based on risk levels. Observations are typically graded using codes such as C1, C2, and C3—where C1 signifies immediate danger. Understanding these codes plays a crucial role in determining the necessary actions to ensure compliance and safety.

How Often Should Fixed Electrical Testing Be Conducted?

Recommended Testing Frequency

The frequency of fixed electrical testing largely depends on the type of installation and its usage. Generally, commercial and industrial properties should undergo testing every five years, while lower-risk residential properties may test every ten years. However, for specific environments, such as those with high electrical loads or vulnerable populations, more frequent assessments may be prudent.

Factors Influencing Testing Schedules

Several factors should be considered when scheduling fixed electrical tests, including:

- Age of Installation: Older systems may require more regular checks.

- Type of Business: Certain industries, such as manufacturing or healthcare, may necessitate increased frequency for safety.

- Environmental Conditions: Factors like humidity or exposure to chemicals can affect the integrity of electrical systems.

Best Practices for Scheduling

Implementing a systematic approach for scheduling fixed electrical testing is crucial for maintaining safety standards. Best practices include keeping detailed records of previous testing results, ensuring visibility into potential hazards, and aligning testing schedules to align with maintenance cycles of other critical systems within the facility.

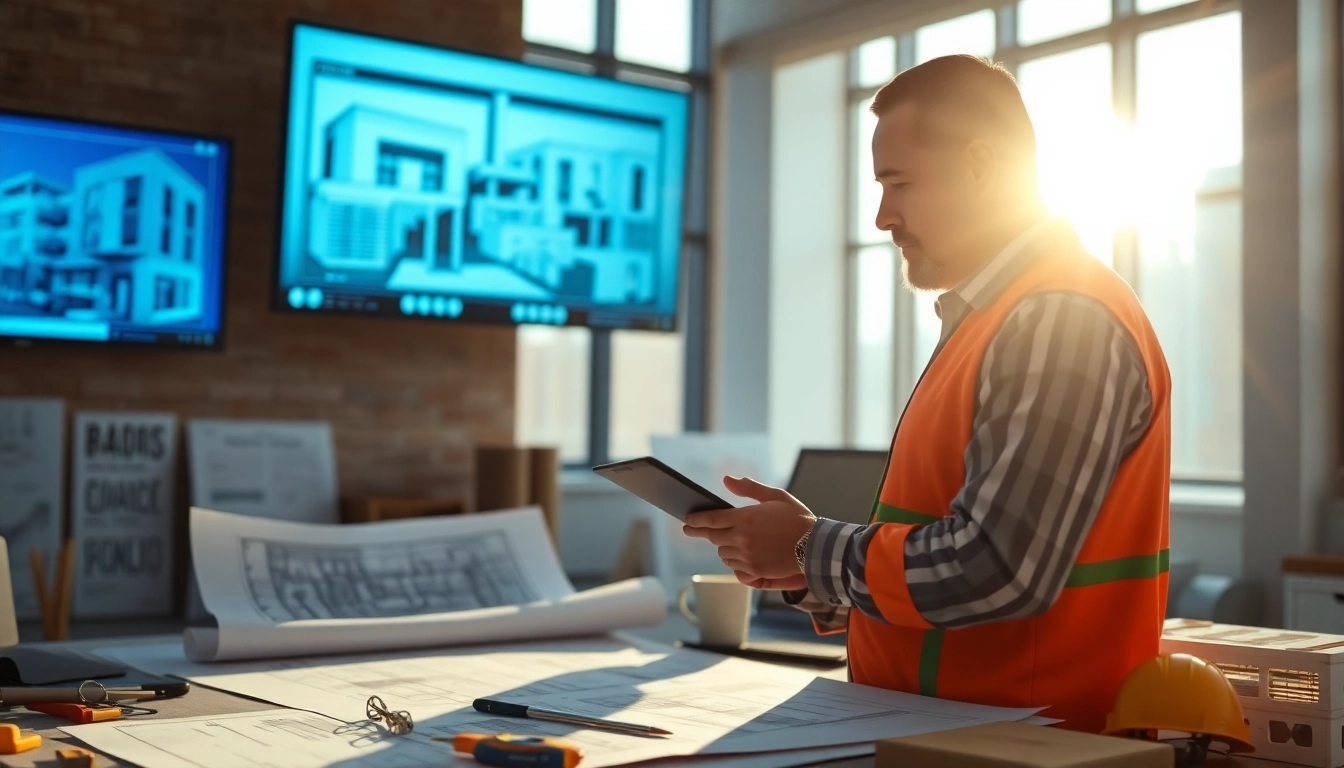

Selecting a Qualified Electrical Testing Provider

What to Look for in a Provider

Choosing a competent electrical testing provider is vital for ensuring accurate results and compliance. Essential factors to consider include:

- Accreditations: Verify qualifications and certifications from recognized regulatory bodies.

- Experience: Evaluate the provider’s track record and experience in your industry’s specific requirements.

- Equipment: Ensure they utilize up-to-date, advanced testing tools.

Questions to Ask Before Hiring

Before hiring an electrical testing provider, potential clients should inquire about various aspects, such as:

- What specific tests will be performed during the assessment?

- How long will the testing process take and what will be the impacts on business operations?

- Can they provide references or case studies from similar clients?

Evaluating Cost vs. Quality

While cost is a significant factor, it should not be the only criterion for selecting an electrical testing provider. Quality of service can greatly outweigh initial cost savings. Investing a little more upfront in a reputable provider may yield long-term savings by preventing issues that could lead to injuries, equipment damage, or compliance failures. Clients should balance value and quality when making their decision to ensure both safety and service excellence.

Post Comment