Why Redditch Powder Coating is Your Best Choice for Durable Finishes

1. Understanding Redditch Powder Coating

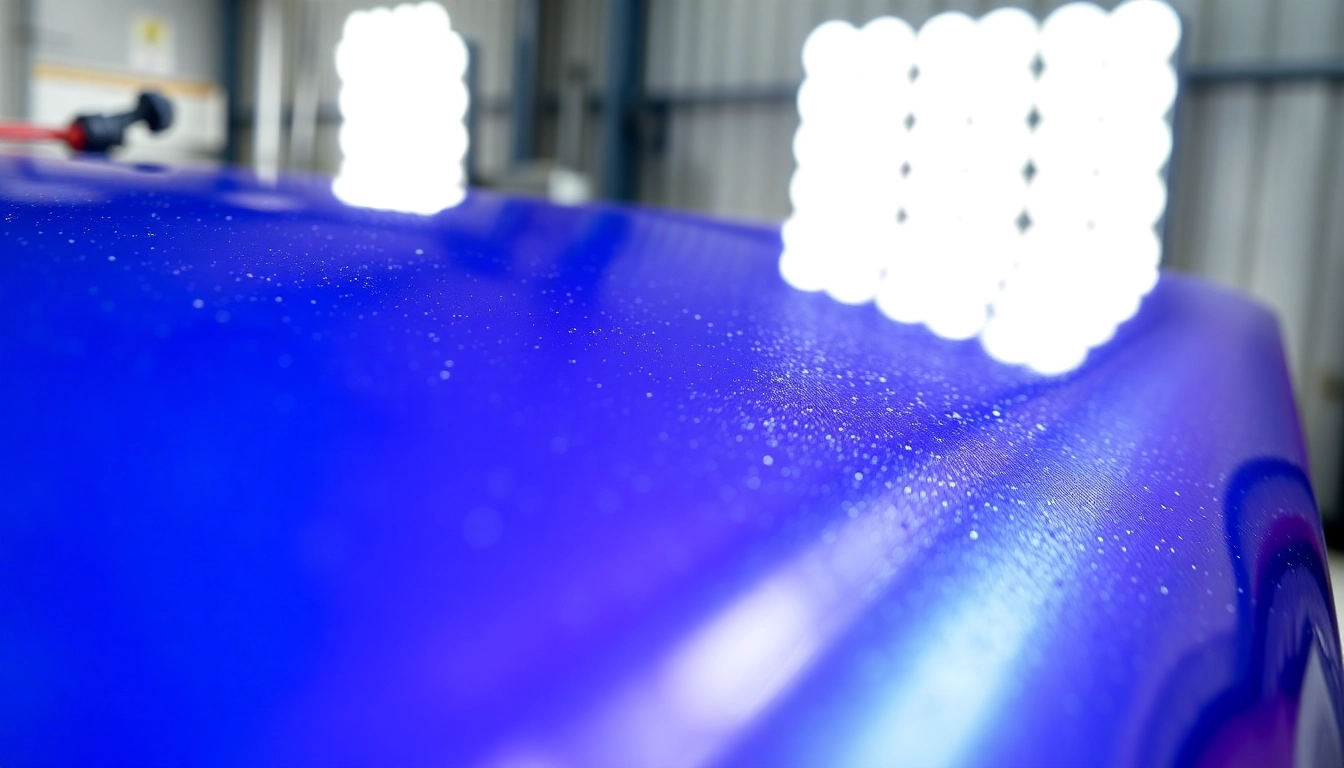

When it comes to enhancing the durability and aesthetic appeal of various products, redditch powder coating is a method that stands out. This innovative coating technique, first adopted in the UK, has become increasingly popular in Redditch, a town known for its manufacturing prowess. But what exactly is powder coating, and why should it matter to you?

a. What is Powder Coating?

Powder coating is a modern method of applying a protective and decorative finish to a wide range of surfaces, particularly metals. Unlike traditional liquid paints, which rely on solvents to keep the binder and filler parts in a liquid suspension, powdered coatings are made from a mixture of finely ground particles of pigment and resin, which are then electrostatically charged. This allows them to adhere to the surface before being cured under heat to form a hard, durable finish.

b. The Advantages of Powder Coating in Redditch

The advantages of powder coating over traditional painting methods are numerous, especially for industries in and around Redditch:

- Durability: Powder coatings are more resistant to chipping, scratching, fading, and corrosion. This makes them particularly suitable for harsh industrial environments.

- Eco-Friendly: The process generates fewer VOCs (volatile organic compounds), making it a more environmentally friendly option. Additionally, any overspray can often be recycled, reducing waste.

- Versatility: With a wide range of colors and finishes available, from matte to glossy and everything in between, powder coating can be tailored to fit specific aesthetic and functional needs.

- Cost-Effectiveness: The long-term savings on maintenance and durability can offset the initial investment in powder coating services.

c. Ideal Applications for Powder Coating

Powder coating is a versatile solution suited for various applications across multiple industries. Some ideal applications include:

- Automotive Parts: Enhancing the aesthetics and providing a protective layer against environmental wear.

- Architectural Components: From window frames to railings, powder-coated surfaces can endure the elements while looking stunning.

- Furniture: Outdoor furniture particularly benefits from powder coating, which resists fading and damage from atmospheric conditions.

- Industrial Equipment: Machinery and components that require a high durability finish are commonly powder coated to withstand rigorous operation.

2. The Powder Coating Process Explained

Understanding the powder coating process is essential for anyone interested in leveraging its benefits for various applications. This section aims to demystify the steps involved.

a. Pre-Treatment Steps for Optimal Results

The quality of powder coating significantly depends on the pre-treatment of the surface. The following steps are crucial:

- Cleansing: The surface must be free from contaminants such as oil, dirt, and grease. This is typically achieved through alkaline cleaning or solvent degreasing.

- Etching: For metals, etching can enhance adhesion. It involves applying a chemical solution that roughens the surface, allowing the powder to grip better.

- Rinsing: After cleaning and etching, surfaces should be thoroughly rinsed to remove any remaining chemicals.

- Drying: Surfaces must then be dried, as any moisture can interfere with the adhesion of the powder coating.

b. The Application Method: Spray vs. Other Techniques

The next step in the powder coating process is applying the powder. The most preferred method is electrostatic spray deposition (ESD), which uses an electrostatic charge to attract the powder to the grounded object. Other application methods include:

- Fluidized Bed Coating: Suitable for smaller items, this method allows the powder to be fluidized in a chamber and then dipped with the item, giving it a uniform coating.

- Manual Spraying: While less common for industrial applications, manual spraying can be used for intricate items or when precise control is needed.

c. Curing: How It Impacts Durability

Once applied, the coated item goes into an oven where heat cures the powder, transforming it from a dry state into a unified solid. This curing process is vital as it affects the quality and durability of the coating. Typically, curing times and temperatures can range from:

- Temperature: 160°C to 200°C (320°F to 392°F)

- Time: 10 to 30 minutes depending on the thickness of the coating and the specific powder formula used.

The result of proper curing is a hardened finish that is resistant to scratches, impacts, and environmental factors.

3. Choosing a Powder Coating Provider in Redditch

Selecting the right provider for your powder coating needs can significantly impact the quality and longevity of the finish. Here are key considerations when choosing a provider.

a. Key Qualities to Look For

When searching for a powder coating provider in Redditch, consider the following qualities:

- Experience: Look for companies with a proven track record in powder coating services, ideally with both industrial and commercial experience.

- Certifications: Check if they hold relevant certifications that demonstrate compliance with industry standards.

- Range of Services: Opt for providers offering comprehensive pre-treatment and post-coating services.

- Quality Assurance: A good provider will have quality assurance processes in place to ensure consistent results.

b. Comparing Local Services: Price & Quality

In Redditch, multiple companies offer powder coating services. Here are some ways to compare:

- Request Quotes: Get quotes from different providers but remember that the cheapest option isn’t always the best. Assess what is included in the service.

- Review Samples: Ask for samples of previous work to evaluate quality.

- Client Reviews: Online reviews and testimonials can provide insights into the satisfaction of other customers.

c. Customer Testimonials and Case Studies

Reputable powder coating services should share testimonials and case studies showcasing their work. Engaging with previous customers or reading reviews online can also provide valuable insights into a provider’s capabilities. Look for:

- Before-and-after photos.

- Specific examples of projects relevant to your industry.

- Details on challenges they overcame during projects.

4. Common Issues and Solutions in Powder Coating

Despite its many advantages, several issues can arise during the powder coating process. Understanding these challenges helps ensure a high-quality finish.

a. Troubleshooting Defects: What to Watch Out For

Identifying issues early can prevent significant problems down the line. Common defects include:

- Orange Peel Effect: This occurs when the finish has a wavy texture due to improper application or insufficient curing.

- Blistering: Caused by trapping moisture during the curing process, leading to bubbles on the surface.

- Uneven Coverage: Often due to improper electrostatic charge or incorrect spraying distance.

b. Preventive Measures for High-Quality Coating

Preventive measures can greatly reduce defects. Strategies include:

- Proper Training: Ensure all employees are well-trained in powder coating techniques.

- Regular Maintenance: Equipment used in the application should be regularly inspected and maintained.

- Environmental Control: Maintain optimal working conditions regarding humidity and temperature.

c. Maintenance Tips for Longevity

To maximize the lifespan of powder-coated items, consider the following maintenance tips:

- Regular Cleaning: Rinse off dirt and debris regularly to prevent corrosion.

- Avoid Abrasive Cleaners: Use soft cloths and gentle cleaners to avoid scratching the surface.

- Inspect for Damage: Periodically check for chips or scratches so that you can address them before they worsen.

5. Future Trends in Powder Coating Technology

The powder coating industry is evolving, with innovations and technological advances that hold promising potential for the future. Below are trends to watch:

a. Innovations in Eco-Friendly Powder Coatings

As environmental regulations tighten, companies are innovating and adopting eco-friendly powder coatings that reduce moisture and organic contaminant usage in the production process. Bio-based powders are also emerging as substitutes for traditional resin formulations.

b. Emerging Application Techniques

Technology is leading to the development of new application techniques that improve efficiency and quality. For example:

- Robotic Spraying: Helps achieve uniform spray patterns and reduces the chance of human error.

- Advanced Electrostatic Technologies: Innovations here enhance the electrostatic charge, leading to better coverage and adhesion.

c. Market Predictions for Redditch Powder Coating Services

The future of the powder coating market in Redditch looks promising, with growing demand in automotive, architectural, and consumer goods sectors. As more manufacturers embrace sustainable practices, quality powder coating services are expected to expand. Industry experts anticipate increased investment in technology and training to meet these demands efficiently.

Post Comment